I have become ever-mindful about the foods I am eating, and increasingly more so in recent months.

When I learned that Land O’ Lakes butter was made with GMO-grain fed cow’s milk, I decided to pose the question to our own Oregon Coast neighbor, the Tillamook Creamery.

Here is how that exchange went.

My email to them:

message: I recently became aware that Land O’Lakes uses GMO materials in the manufacture of their butter. I am assuming this is related to the diet of their herd, but who can say?

My question is, does Tillamook use GMO- affected products in the manufacture of your butter, milk, ice cream, cheese, yogurt, etc.

A lot of us who buy these products have chosen Tillamook because of the proximity of Tillamook, to where we live (also on the Oregon Coast. It allows us to fancy ourselves loca-vores (despite so many of the products being made elsewhere, in reality).

But all of us are careful to try to avoid GMO products and processes which use a GMO-affected product. We need some straight answers about how Tillamook utilizes GMO affected products and grains.

… after a week or so, this was their response:

Hi Rachel,

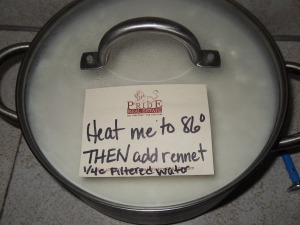

Thank you for reaching out to us directly. We know the GMO topic is a sensitive and important one to some consumers, and we want to be as accurate as possible in responding to questions and concerns about it. First and foremost, the core ingredients in all our products are milk and cream of the highest quality produced in the most natural way possible, and neither of these ingredients have exposure to GMOs. In regards to some of the additive ingredients – particularly to our ice cream and yogurt – the answers are a bit more complex. At this time, and in the absence of any clear standards or definitions around genetically modified substances, it is hard to categorize which ingredients are – with certainty – GMO-free. We do use some ingredients like natural flavoring (e.g. sugar or corn syrup for sweetening), natural coloring (e.g. beet juice), and stabilizers (e.g. corn starch and soy lecithin) that have the possibility of being derived from GMO sources because of the pervasiveness of GMOs in agricultural crops in the United States.

Our farmers know that healthy cows make the best quality milk and part of this is a healthy diet. The farmer-owners and all the dairymen who supply milk for Tillamook dairy products use a variety of forages and grains for feed. While the mixture varies dairy to dairy, it’s likely to include a mix of grass, alfalfa, some corn silage, and grains such as barley or soy. All of this is balanced by a nutritionist who also adds a vitamin/mineral supplement to ensure the healthiest cows possible, and thus the highest quality milk. The feed used by our farmers and suppliers is both home grown on our farmer’s fields and purchased.

At this time, and in the absence of any clear standards or definitions around genetically modified substances, it is hard to know if the feed purchased for every cow contributing to our milk supply is GMO-free. In today’s market, it is extremely difficult to source feed for cattle that is 100 percent verified as GMO-free, given how pervasive GMOs are in the grain supply chain. Even organic feed for organic farms is extremely difficult to verify as GMO-free because of cross-pollination.

I hope this information is helpful. Please let me know if you have any more questions.

Thanks,

| Callie O’Sullivan |

| Consumer Loyalty Team |

| Toll-free: 1-855-Loaf-Love (562-3568) |

| Tillamook.com | Tillamook Twitter | Tillamook Facebook |

________________________________________________________________

My hat’s off to Tillamook for responding to my inquiry in an intelligent and sensitive manner.

I appreciate them not treating my question as trivial and also for giving me the most thorough explanation possible, under the circumstances.

I really wanted the answer to be a very simple and straight-forward “No”. But that isn’t the world we live in.

I will continue to use their butter and cheese (even though they refuse to remove corn syrup from their ice cream 😦 )

Just thought others might want to know how this company responded to a direct question about GMO-affected products.